Life Cycle Assessment: A Comparison of hardwood and Medium Density Fiberboard (MDF) dining tables

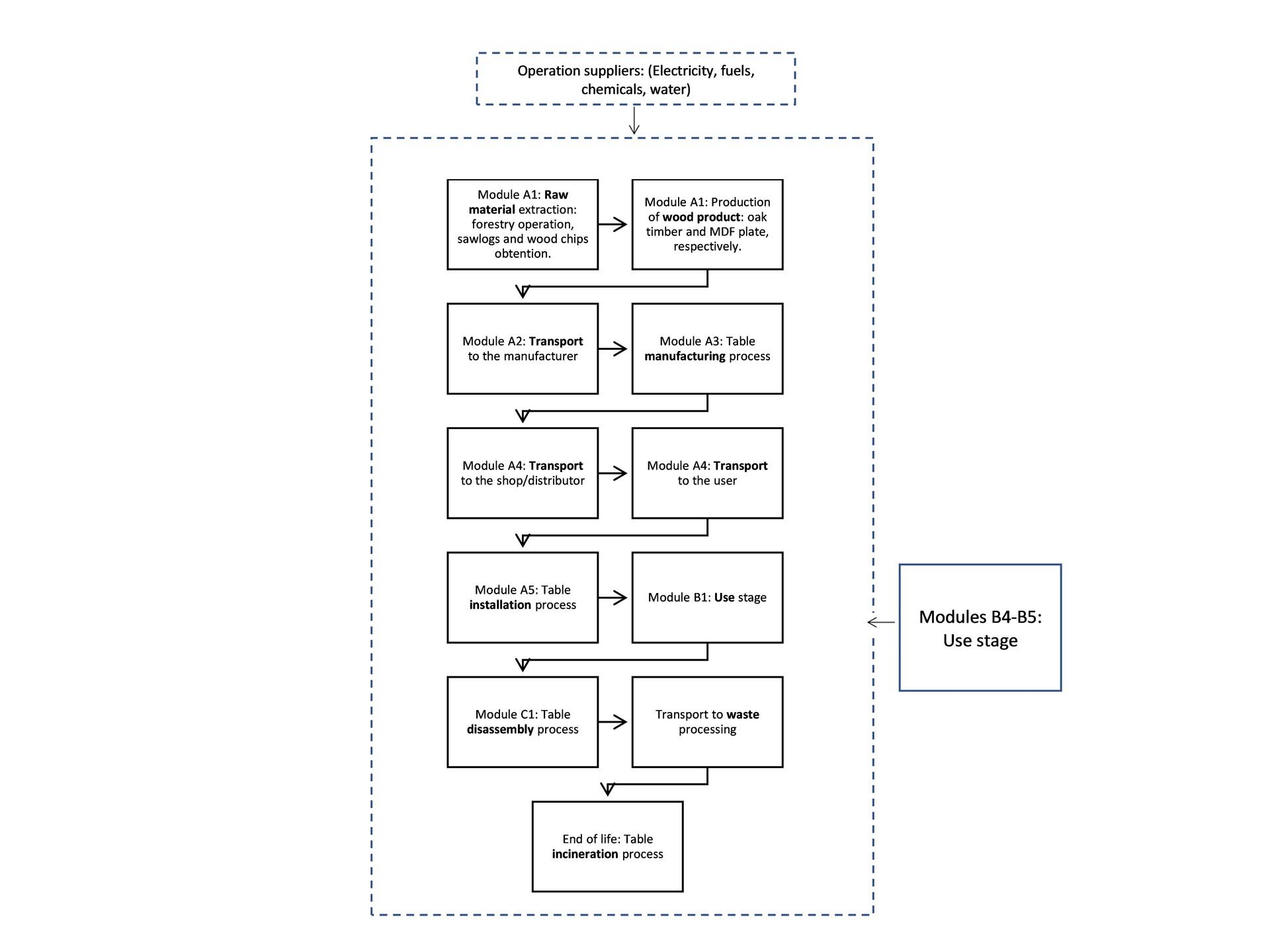

Environmental impacts associated with the furniture industry have become of increasing importance. Generally, most of the impacts of a product are not created at a production facility, but along the supply chain. In order to control the impacts in each stage, it is necessary to measure them in the first place, i.e. by conducting a Life Cycle Assessment (LCA), a tool that quantifies and evaluates a broad scope of environmental impacts from the selected life cycle of a given product. Life Cycle Assessments are one of the most profound ways for the furniture industry to promote environmentally friendly products and business models with scientific evidence. The following figure shows our research frame:

This report shows the LCA results of two case studies of wooden furniture. The compared products are an oak hardwood lumber and a Medium Density Fiberboard (MDF) dining table. The wooden tables selected are representative standard pieces taken from the Swiss market. In both cases, the raw material is taken from Poland. The MDF table was produced in Switzerland whereas the hardwood table was produced in Poland. CIVAG refers to this study as a “Traditional Case Study” because it does not include the company’s business model, but instead it aims to understand the typical life cycle of a dining table. The environmental impacts were measured in Europe, including countries such as Switzerland, Germany and Poland using the life-cycle inventory method through the Software OpenLCA.

Primary data was collected on a per-unit basis of 1 piece of furniture to find material flows and energy use. On the other hand, the environmental impact is measured with three variables: The energy consumption in MJ, the water consumption in L and the impact categories, which groups emissions into different effects on the environment, which then are put together in one variable called Environmental Cost Indicator ECI.

The cumulative allocated energy consumption during the cradle to grave life cycle assessment of 1 piece of furniture made of hardwood lumber corresponds to -3,80 GJ/m3, while the energy for 1 piece of furniture made of MDF corresponds to -1,50 MJ/m3. The negative value obtained is due to the energy recovery process through incineration during the waste disposal stage at the furniture’s end of life. This is the typical practice in Switzerland, from which 4% of the energy of the country is obtained. Now, ignoring the waste disposal stage of the cycle and thereby its energy recovery, the cumulative allocated energy consumption is 9,66 GJ/m3 and 8,93 GJ/m3 for the hardwood lumber and the MDF table, respectively.

The materials used and energy consumed during the manufacturing of the wood furniture materials - lumber and Medium Density Fiberboard (MDF) - affect the furniture’s environmental performance significantly. However, this report shows that other processes such as the transport and the manufacturing of the final wood product have a higher impact on the furniture’s environmental performance.

Finally, the emission data obtained through the modeling estimated a total carbon dioxide production of 2410,9 and 2782,3 kg CO2/m3, respectively, considering all impacts in the cradle to grave life cycle assessment. The amount of carbon dioxide emitted in MDF case exceeds hardwood lumber emissions. In terms of other emissions, the MDF case has greater impact in all the categories than hardwood lumber. The exact values can be seen in the report. As another example total water consumption during the life cycle corresponds to 6,38 and 25,08 L respectively.

The impact specific to the CIVAG circular rental model is not assessed in this report, but in a subsequent one.

Here you can access our LCA Analysis: CIVAG LCA Report